If you’re in the promotional products or private label space, you’ve likely come across the term OEM. But what exactly does “OEM meaning” refer to, and why is it important when working with suppliers?

This article is designed to break down OEM meaning in plain language, so you can understand how it fits into your business and why it matters when creating custom products for your clients.

OEM Meaning Explained

OEM stands for Original Equipment Manufacturer. In simple terms, it refers to a factory that produces a product based on specifications provided by another company. That company then brands and sells the product as its own.

For example, let’s say a promotional company wants to offer custom water bottles with their client’s logo. Instead of making the bottles themselves, they send the design and logo requirements to a factory. The factory manufactures the bottles, prints the logo, and packages them according to the company’s request.

When the customer receives the product, it looks like it came directly from the promotional company, even though a third-party factory produced it. That is what OEM is all about.

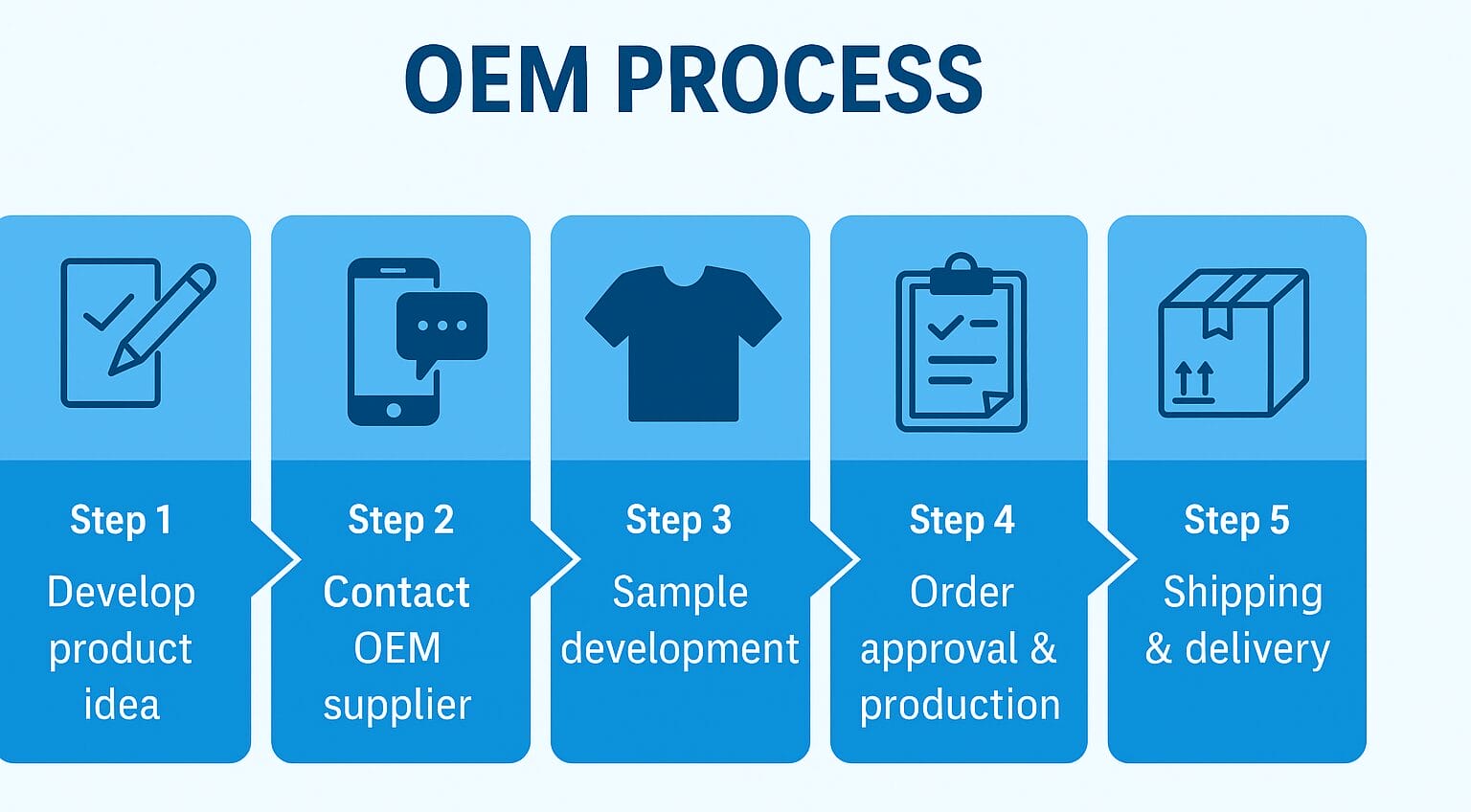

OEM Process (Step by Step)

Understanding the OEM process helps you plan better and avoid delays or miscommunication. Here is how it usually works from start to finish.

Step 1: You develop a product idea

Start with a clear concept. This might be a rough sketch, a photo of something similar, or a detailed list of features.

You should also think about the materials, size, colors, function, and how the product will be used.

The more detail you provide upfront, the smoother the next steps will be.

Step 2: You contact an OEM supplier

Next, you find a factory that specializes in the type of product you want to make. You send them your idea, and they confirm if it is possible to produce.

They will ask follow-up questions about the material, size, packaging, logos, and quantity.

After reviewing your request, they will send a quote including the unit price, sample fee, minimum order quantity, and estimated production time.

Step 3: The factory produces a sample

Once you accept the quote, the factory makes a prototype based on your design. This is your opportunity to review the quality, sizing, colors, and branding before mass production commences.

If something is not right, you can ask for changes and a second sample. Some factories offer unlimited revisions, while others may charge for adjustments.

Step 4: You approve and place a bulk order

After you approve the final sample, you sign off on the order. The factory will usually require a deposit before production starts.

At this stage, it is important to confirm:

- The final specs and design

- The delivery timeline

- Packaging requirements

- Any logos or artwork files

Mass production begins once everything is approved and payment is received.

Step 5: The factory ships your branded products

Once production is complete, the goods are packed and shipped based on your preferred international commercial terms. This could be FOB (Free on Board), CIF (Cost, Insurance, and Freight), or another shipping method.

If you have your freight forwarder, they can manage customs clearance and delivery. Otherwise, the factory may help arrange shipping to your warehouse or distribution center.

The final products arrive fully branded and ready to sell or distribute.

Benefits of OEM

Many businesses, especially in the promotional products space, choose OEM because it lets them offer a wide variety of branded items without owning a factory. By outsourcing production, they can focus more on sales, customer service, and brand building.

OEM meaning goes beyond the basic definition, it comes with several practical advantages when applied to sourcing:

- Full control over the product’s appearance, including design, size, color, and branding.

- No need to invest in factory setup, staffing, or machinery.

- Faster entry into the market with made-to-order products tailored to niche audiences.

- Greater ability to offer a wide product range without increasing internal workload.

- Easier brand positioning through unique, custom-designed merchandise.

These benefits make OEM an attractive model for many companies. It allows them to scale their product offerings without increasing overhead.

Potential Drawbacks of OEM

To get the most out of OEM sourcing, it’s important to understand the challenges that can affect cost, speed, and product quality. Here are some common ones:

- It usually requires high minimum order quantities, making small-scale orders harder to manage.

- Sample development, revisions, and tooling can lead to longer production timelines.

- Initial setup costs like sample fees and mold charges increase upfront investment.

- Intellectual property may be at risk without proper contracts or NDAs.

- Communication gaps with overseas factories can lead to delays or errors if not managed well.

These challenges do not make OEM a bad choice, but they do require careful planning, clear instructions, and working with the right partners.

OEM vs ODM vs White Label

It’s easy to get confused by these terms OEM, ODM, and white label. They often show up together in sourcing discussions, but they do not mean the same thing.

If you’ve ever felt unsure about which one fits your project, you’re not alone. Many people mix them up because they all involve working with a manufacturer. But the level of control, customization, and branding is very different in each model.

Here’s a simple breakdown to help you understand the key differences:

| Term | What It Means | Who Designs It | Can You Customize It | Who Sells It |

|---|---|---|---|---|

| OEM | A factory makes a product to match a brand’s request | The brand | Yes | The brand (with logo) |

| ODM | A factory designs and makes a product the brand can buy | The factory | Some customization | The brand (adds logo) |

| White Label | A generic product made by the factory, sold to multiple brands | The factory | No | Any brand (just re-label) |

Understanding how these models differ will help you make smarter sourcing decisions.

Use OEM when you want something fully custom.

Use ODM when speed matters and partial changes are okay.

Use white label when you want the fastest route to market with minimal changes.

Common Examples of OEM Products

OEM manufacturing is widely used in promotional products, even if it’s not always called by name. Think of:

- Tech accessories such as phone chargers and Bluetooth speakers

- Promotional items like pens, mugs, notebooks, and umbrellas

- Apparel items such as printed T-shirts, polos, and branded caps

- Kitchen tools, fitness gear, and eco-friendly giveaways

These categories are especially common in the promotional industry because they offer strong branding opportunities and are frequently ordered in bulk for events, giveaways, or company stores.

Why It Matters in Our Work

You might not handle sourcing directly. But knowing the basics of OEM still helps. It lets you make better decisions, set clear expectations, and avoid common mistakes.

When you understand the OEM meaning, you also understand:

- Why sampling and quality control are essential before full production

- How branding fits into the product creation timeline

- What to expect in terms of lead times, MOQs, and packaging options

Grasping these points will give you a clearer view of the entire production process and make it easier to manage client expectations. It also builds your confidence when discussing orders, reviewing product specs, or following up with suppliers.

Partner with a Reliable OEM Supplier

Understanding the OEM meaning is just the start. At Sphere Resources, we work directly with OEM factories to produce custom merchandise, retail packaging, and promotional products. We help clients finalize designs, manage sampling and revisions, and oversee quality checks before mass production.

Our team also coordinates shipping and packaging to match your branding, so you receive ready-to-sell products with fewer delays and less back-and-forth.

Contact us to talk through your project or book a free consult.